I have never been reticent in expressing my love and admiration of America. I love the Americans who call it home.

As an Australian, I admire the exploits of their armed services ( when I was a boy during WW2 ) but it was my experience of living there in 1976 that cemented the attitude I developed and still have today.

America is presently going through a very bad patch and has dragged the rest of the Western World with it.

Since the end of WW2, the only thing that has stood between Communism and the life that most of the free world enjoys is America. The untold generosity to every beleaguered nation on this planet has not been appreciated by most of them.

Thank God for America.

In 1937 there were reports from American missionaries, and others who had visited China, about the atrocities being committed by the Japanese Army against Chinese civilians.

One of these was retired US Army Air Force General Claire Chenault who urged the President to declare war on Japan. These reports were received favourably with a majority of the Chiefs of Staff and the President in favour of attacking Japan. There was, however, one dissenting voice. That was General George Marshall, chief of the Army who stated that America was not capable at that time to engage in a war with Japan and the idea was dropped.

Following the end of WW1, and especially after the Peace Conference of 1919 when the disarmament proposals of then President Woodrow Wilson were adopted, American war production stopped and the few that remained were discouraged or penalised for producing war materials and weapons. The rationale was that if America had no military forces then it would be incapable of engaging in any war but more particularly in a foreign war. Public feeling was supportive of this isolationist approach which was reinforced by its Neutrality Acts.

Thankfully, President Roosevelt was a far-sighted leader and he took Marshall’s opinion seriously as the clouds of war were gathering in Europe.

On 14th November, 1938 a conference at the White House decided that in light of the Munich crisis, a planned gradual expansion of the Army was decided.

Video made 10 years ago

By 30th November, The War Plans Division produced a blueprint to expand the regular Army from 167,000 to 280,000 over a 2-year period and the National Guard from 190,000 to 240,000 enlisted men.

By 1st July, 1939 these figures had increased to 189,867 plus 110,000 reserves and 200,000 National Guards.

These enlistments were referred to as the Protective Mobilisation Plan. Simultaneously a second plan, the Industrial Mobilisation Plan was adopted to prepare for the economic mobilisation of the nation.

When war broke out in Europe on 1st. September, 1939, the President declared a State of Emergency on September 8th. As the war in Europe intensified the enlistment targets were progressively increased to a million-man army by 1st January, 1941 and 1,400,000 by 1st July, 1941.

On 7th December, 1941 (Pearl Harbour attack day) the recruitments had increased to 1,647,477 including National Guards. Between August and November, 1941, large scale manoeuvres were undertaken involving some 900,000 men but much of the equipment used was dummy due to lack of resources available. By 1st October, 1941 only 17 out of 34 Divisions were deemed ready for offensive combat action.

It was estimated at the time that if Germany were to invade the USA it would only need 5 divisions to take the entire country such was the parlous state of readiness and availability of munitions and armaments.

On the industrial front, a War Resources Board was established in August 1939 and disbanded on 30th November. On 25th May 1940 the President initiated the Office of Emergency Management and on 28th May he created the Advisory Commission to the Council of National Defence.

On 18th December, 1941 Congress passed The First War Powers Act which gave the President power to reassign statutory functions of government departments and agencies.

The President knew that the wheels of government and the military worked too slowly in an emergency. He also knew that America at the time was the most efficient industrialised nation on Earth. In no other country was the average working family able to afford to own a motor car or a refrigerator and many other comforts of life that Americans took for granted.

He realised that the only solution to reaching the goals set was to engage private industry and to that end he chose two leading industrialists to take control of industrial production. In that, he was strongly supported by General Marshall. His first choice was William S Knudsen, then President of General Motors.

Bill Knudsen was born in Denmark in 1879 and migrated to America in 1900. In 1902 he began working for a bicycle factory in Buffalo, NY, which in 1904 began making parts for the Ford Motor Company. Ford purchased this company in 1911 and in 1914 he transferred to Ford’s Detroit plant where he was appointed to supervise all of Ford’s 28 assembly plants throughout the USA. He was also appointed director of Ford’s construction of submarine patrol boats for the US Navy during WW1.

In 1922 Knudsen had a falling out with Henry Ford and left to join General Motors. In 1924 he was appointed president and general manager of the Chevrolet Division of GM and in 1937 became president of the entire General Motors Corporation.

In 1940, President Roosevelt appointed him director of industrial production for The National Defence Research Committee. In 1941 he was appointed head of the US Office of Production Management. He was invested with the Army rank of Lieutenant General in 1942 in charge of production for the War Department until July, 1945 when he returned to private business.

In 1941 America manufactured 3,000,000 cars. In the following years until after the end of the war, 139 were made and these were used as staff cars. Knudsen’s background in mass production line manufacturing rendered him a perfect choice for the roles he was given by the President. Life was not easy for him to carry out these functions prior to the declaration of war with Germany and Japan in December, 1941.

Knudsen adopted a radical approach to war production. He allowed private companies to carry out government contracts without interference and he allowed them to make a profit. This was a different approach to what was happening in England and Europe generally where public servant oversight and intrusion was rampant in war production factories. The President knew that Knudsen knew that American industry had the know-how to do what it was being asked to do. His only interest was results. At the same time, America was blessed with a large labour force that had been very much under-employed during the 1930s depression.

The huge increase in opportunity for work was grasped by the American worker with enthusiasm.

After Dunkirk, the RAF was reduced to a total of approximately 700 airworthy aircraft.

It did not have the capability to replace what it had lost in a short space of time so it looked to America for supply. At the time America was not noted as a producer of aircraft and at the time there was no American company that produced fighter aircraft that would meet the standards required to fight the air war in Europe.

Britain approached the North American Aircraft Company to manufacture an aircraft that had been designed by the Curtis Aircraft Company. This was the P.40, or commonly known as the Tomahawk and it was as good as one could get at the time. North America replied that they would produce the prototype of a revised improved design in 120 days, a formidable undertaking in the eyes of conventional aircraft manufacturers but typical of the American “can do” ethic. North American completed their task with 3 weeks to spare and the P51 Mustang was born. Britain placed an order for 320 of these aircraft and North American went immediately into production.

The Mustang was designed to take advantage of American mass-production techniques. It was revolutionary in many respects predominantly for its construction with flush finishing lightweight rivets. The Mustang’s reception in Britain was mixed. Its top speed of 380 MPH and excellent manoeuvrability were admired but its performance above 15,000 ft was poor so it could only be used for low-level combat and with German invaders operating at 20,000ft or more its use in the defence of Britain was very limited.

Fortunately, the chief test pilot of Rolls Royce had flown the P51 and recognised that if it were fitted with one of the new breed of Rolls Royce Merlin engines it would be a far different aircraft. The problem was that Britain did not have the manufacturing capacity to produce the number of Merlin engines required for the P51. It was fully committed to producing engines for Spitfires and Hurricanes. The only option was to have them produced in America.

When Bill Knudsen received a call from Britain his immediate reaction was to contact the only company capable of carrying out the order; the Ford Motor Company. Ford was already an aircraft manufacturer. The Ford tri-motor, an aircraft similar in appearance to the Fokker that Kingsford Smith flew in his pioneering flight from Oakland to Brisbane, was already an established model for personal and freight transport.

Knudsen approached Edsel Ford, the son of Henry and then the president at Ford. He accepted the order for 6,000 Rolls Royce Merlin engines but was overruled by his father, Henry, who refused to manufacture engines for the British. Henry Ford was an avid supporter of American isolationist policy. He was adamant that Ford would not produce or sell its products to countries involved in war and, further, he was an arch enemy of President Roosevelt, a Democrat whom he considered was anti-free enterprise.

Henry Ford’s attitude to President Roosevelt was not confined to him alone. As the architect of the “New Deal” which was conceived by Roosevelt to remove the effects of the 1930s depression, severe restrictions and profit limitations were imposed on private businesses. This was resented by the vast majority of American business and particularly by big business which was the primary target and victim.

Knudsen knew that it was a hopeless task to convince Henry Ford to change his mind. Ford announced in the press that his company would not produce any war materials for countries at war so Knudsen then turned to the Packard Motor Company which had been a producer of luxury cars since 1910 and was well-versed in the science of mass production techniques.

When the plans and specifications arrived from Britain the American engineers could not make head or tail of them. The British manufacturing techniques were so far removed from the American methodology of mass production. The American engineers set about to convert the British plans and specifications to American mass production language where manufacturing processes were carried out by machines rather than skilled manual labour which was the practice in British factories. When Packard production got into full swing it was producing engines at triple the rate of British factories and their product was considered to be superior as well. Every Packard Merlin engine came with its own set of tools and spares. It was loved by British maintenance engineers as well as the pilots who flew the planes that were equipped with them.

In 1939 German aircraft production was 8,295. Britain produced 2,141. By 1941 German production had increased to 12,401 and American to 18,466. The Germans were suffering a rate of loss greater than its ability to replace them. Thanks to the back-up of American production Britain was able to maintain the replacement of lost aircraft at a rate equal to its own rate of loss.

Last time, I discussed the role of America in the defence and defense of the allies in the lead up to World War II. When, thanks to the back-up of American production, Britain was able to fight the threat from its enemies. As the war progressed, the allies were facing greater threats and assembly lines were needed to keep the allies armed.

On 7th December Japan attacked the American base at Pearl Harbour, Hawaii. Tension between the two countries was extreme and had been rising for a long time starting with the American disapproval of the Japanese Army behaviour in China. As a sanction, America progressively denied supply of materials to Japan until it reached breaking point with the complete embargo on oil supplies without which Japanese industry could not operate.

Japan was well aware of the American vulnerability of weak defenses and there was strong support within the military to invade California. The decision not to invade was due entirely to the fact that it was known that there were many guns in the hands of the civilian population and California was very far from Japan which made supply a logistical nightmare.

Attention then swung to an attack on the American Pacific fleet based at Pearl Harbour to put it out of action and eliminate the risk of it coming to the aid of its army in the Philippines and its allies if and when Japan decided to invade SE Asia to secure its vital supplies.

There were several strategies debated within the Japanese high command and Admiral Yamamoto, the senior officer of the Japanese navy was appointed to plan and lead the attack. Yamamoto had been stationed in Washington as a naval attaché and was very conversant with the potential of American industry. He accepted the appointment on the condition that the strike would be carried out according to his instructions and that condition was accepted.

Yamamoto laid down three targets to be achieved if the raid was going to proceed.

First was that the American carrier fleet had to be destroyed. Yamamoto knew from the experience of the sinking of the British battleships Prince of Wales and Repulse in December 1939 that the days of the battleship were numbered as against air power and that the future lay in aircraft carriers.

Second was that the oil storage tanks at Pearl Harbour had to be destroyed so that American ships based at Pearl Harbour did not have the ability to sail back to the US mainland.

Third was that the raid would inflict so much damage that America would be forced to sue for an armistice.

It is now a matter of record that the raid failed to meet Yamamoto’s conditions and in the aftermath, he is recorded as saying that “The war is lost. All that we have done is to wake a sleeping giant”.

The American carrier fleet was still at sea when the raid took place and was not even attacked. The loss of the ships in “Battleship Row” had little or no effect on American fighting ability. The oil storage tanks were undamaged and the hope of forcing an armistice vanished with them.

Yamamoto’s lament that a sleeping giant had been awakened was fatally correct. A state of war then existed between Japan and America which threw off the cloak of restrictions imposed by the Neutrality Acts. Adding to the American relief, Germany and Italy declared war on America the next day so that there was now no debate in any quarter about America’s ability or willingness to participate in and supply foreign nations at war as long as they were on the same side as America.

A State of Emergency was declared and the American people were galvanised into a union with one single purpose: to avenge Pearl Harbour.

This new state of affairs also changed the attitude of Henry Ford. He was no longer committed to isolationism but was equally fervently committed to the defense and protection of his country. The debate about production of Rolls Royce engines was long past and a new, more substantial project was on the horizon.

The War Council decided that the key to a successful offensive war against Germany was the four-engined bomber. During the Battle of Britain Germany did not have one. Its bombers were two engined and less formidable as opponents for British fighters. Attention turned to the ways and means of producing a four engined bomber quickly and in large numbers. The selected aircraft was the American B24 Liberator made by the Consolidated Aircraft Company and it was needed in thousands.

CORRECTION: In the beginning of this video, it was said that the B-24 Liberator is the most produced military aircraft of all time. This is not correct. The B-24 is the most produced bomber of all time, but the most produced military aircraft of all time is the Ilyushin Il-2 Sturmovik.

American industry was willing but it was not ready at the outbreak of war. It was still saddled with the lethargy of the depression years, antipathy between the Democrat President Roosevelt and the industrial giants and hang overs of unionism that put a brake on production in the interests of preserving jobs. The war solved these handicaps. The depression was over because there were now more jobs than workers, Roosevelt extended the olive branch of almost carte blanche freedoms and the role of unions became redundant.

It was calculated that America would need to produce 125,000 planes per year. This, in addition to other war materials, was calculated by Knudson to require an expenditure for start-up of $4 billion dollars.

Once again Knudson turned to the Ford Motor Company and this time was greeted with enthusiasm. Henry Ford was no longer interested in making engines or parts. He wanted to build complete aeroplanes and to this end Ford constructed the biggest factory in the world at that time at Willow Run exclusively for the production of the B24 bomber. The Willow Run factory was about 25 miles from Detroit and covered an area of 4,200,000 square feet.

To run a factory of this scale required an outstanding expert with experience and organisational skills. To do this job Ford and Knudsen selected Charles Sorensen a retired Ford employee of 35 years standing who had risen through the ranks from pattern maker to Vice President of Manufacturing. It was he who designed and oversaw the production line of the T model Ford.

Sorensen attended a meeting in Detroit where the requirements were laid before him. On conclusion he returned to his home in San Diego and set to work planning the factory from his meeting notes. Within 24 hours he produced a complete plan for the factory lay-out and production organisation with the prediction that he could produce one B24 bomber every hour. This conclusion was met with derision by the chiefs of the Army and they wanted to stop the contract. But Sorensen prevailed and the Army let a $200 million contract to get it moving. Sorensen’s plan was for two production lines moving at the rate of one movement per hour.

At the outset, production targets were well short of predictions due to constant modifications of the design. In the end Sorensen insisted that the design phase be completed and settled without further modification. Sorensen made a deal with Consolidated that he would build 400 bombers of one design. At the end of that run any further alterations could be made and that was the final alteration. This was essential to maintain a constantly moving production line.

By the end of March, 1943 the production time of 200 hours for a B24 consisting of 1,500,000 individual parts had been reduced by 90%. Sorensen’s initial target of one B24 per hour was achieved and the fastest rate was one every 55 minutes. The mind boggles at the thought of a plane of this size being produced at the rate of one per hour. There were more B24 bombers built during the war that any other type of aircraft on either side and half of them came from the Willow Run factory.

At the same time the other heavy bomber manufacturer, Boeing, based in Seattle had been steadily producing its B17, the Flying Fortress. For several years it had been working on a project for a new revolutionary bomber which was so sophisticated that the Army wanted nothing to do with it so Boeing carried on alone. After 4 years of development work Boeing final settled on the design and produced the B29, known as the Super Fortress. This plane was adopted by the Army on the basis that the island hopping strategy of Admiral Nimitz would take a long time and suffer high casualties. The B24 did not have the range to reach the Japanese home islands so the B29 was brought into the front line.

This plane was so huge that it required a new factory to accommodate its production. Boeing built a new factory at Wichita, Kansas with subsidiary plants being built by other aircraft manufacturers. The War Production Board wanted nothing to do with it so it was left to the American aircraft industry to co-ordinate itself to produce the aircraft. This new factory was bigger than Willow Rum. The plane itself consisted of double the number of parts of the B24 and its sheer size reduced the B24 to medium bomber status.

The most famous aeroplane ever built was, I think, the B29, Enola Gay which dropped the first atomic bomb on Hiroshima on 6th August, 1945. A separate story in itself.

Following the end of the war the factories at Willow Run and Wichita have fallen into disuse and are now largely derelict.

At war’s end Bill Knudsen, the master of manufacturing had left his post. His task was completed three months earlier. On his watch, the American aircraft industry produced 342,000 aircraft at 6 times the rate of production of the rest of the world. Knudsen died in 1947 but he left behind him a legacy that had propelled America into the greatest manufacturing juggernaut the world has ever seen or likely to see. Its capacity to produce the weapons of war has guaranteed the safety of the Western world and will do so for a long time because the techniques developed on Knudsen’s watch are now embedded in American industry as standard practice and shared with its allies unstintingly. The rise of Japanese and Chinese production can all be traced back to what was developed during Bill Knudson’s watch.

Churchill’s speech on 9th February, 1941 when he said “give us the tools and we will finish the job” could also apply to the policies adopted by President Roosevelt who gave Knudsen a free hand to do whatever he thought was best and backed him up with the power of his office.

Two thirds of all of the equipment used by the Allies during WW2 was produced by America. Not only was it supplying Britain, it was also supplying huge quantities to Russia. The perils of the Murmansk convoys are well recorded but in addition, many aircraft were supplied by flying them from Alaska.

Australia relied heavily on American supplies of equipment and munitions. New Zealand less so because its army was always a part of the British army in North Africa and Europe. Its direct engagement with the Japanese was minimal compared to Australia.

At the end of WW2, America had about 6,000 merchant ships. Today it has about 100.

Merchant ships are the lifeblood of international trade and commerce and even more so to island nations like England, Australia and New Zealand. They are also vital to the well-being of otherwise self-sufficient nations like the USA and Canada.

In 1941, England was the victim of an all-out drive by Germany to deprive Britain of its lifeblood of imports without which it could not feed its people. In a speech in 1940 Winston Churchill magnified the extent of this danger when he said that at any given moment 2,000 British merchant ships are in transit on the high seas. The losses of ships sunk by German submarines was huge and Churchill appealed to America for help. In 1941 alone Britain lost 1,300 ships sunk by German U-Boats.

President Roosevelt was sympathetic and supportive of Churchill’s request but he had no ships to spare. On top of that American shipyards were too few and too busy to be able to help. Churchill offered to pay for the creation of new shipyards in America, safe from German air attacks. The President warmed to this proposal and turned to another giant of American industry, Henry Kaiser.

Unlike Bill Knudsen, Kaiser was a self-made uneducated man. Un-educated in the sense that he was not a brilliant scholar. Kaiser left school and skipped town at age 13. Ten years later he was running his own construction company. His great achievement was the construction of the Hoover Dam, one of the greatest engineering achievements ever at that time. He had a talent for organisation built on the back of fierce determination and nous.

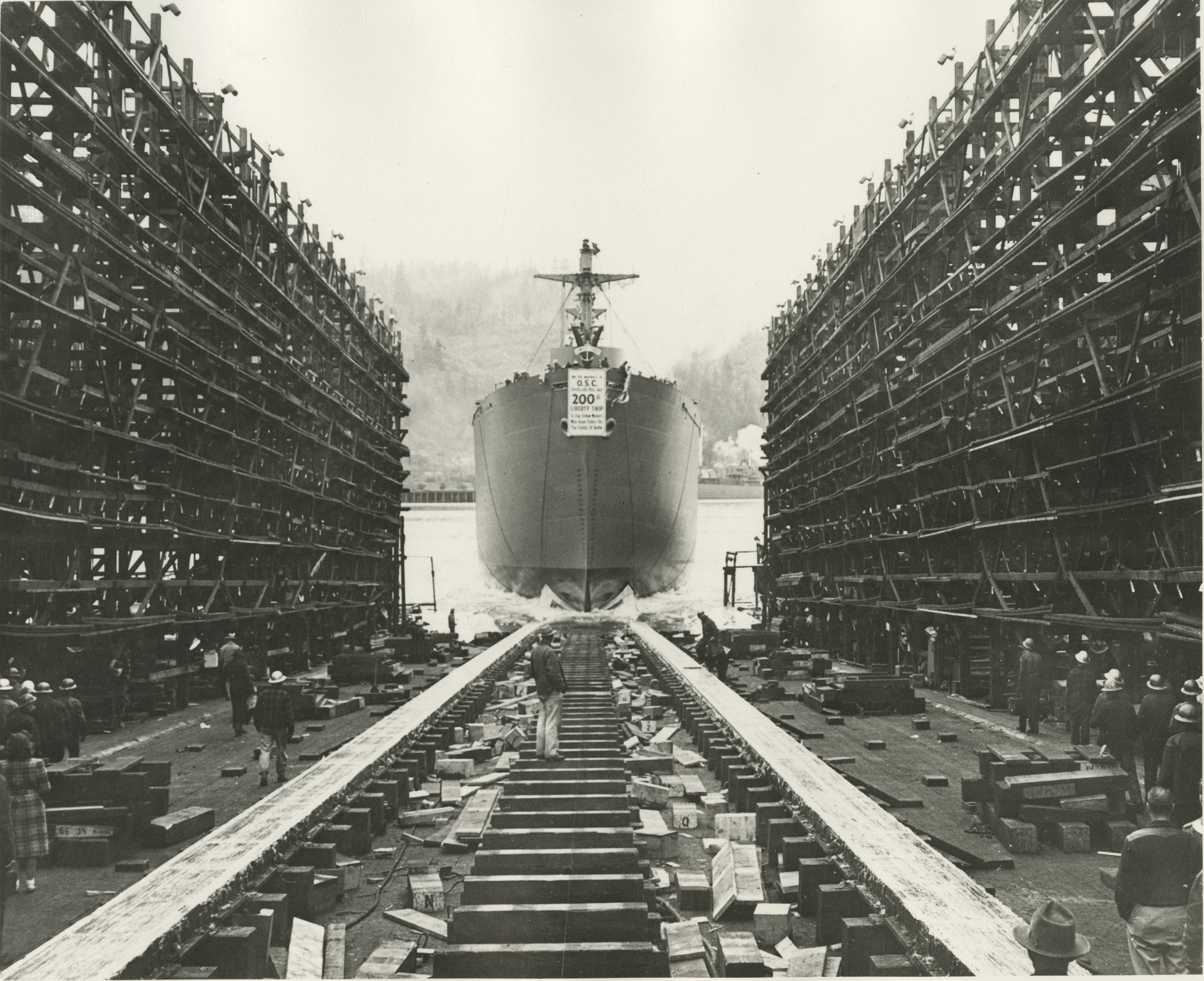

Kaiser offered to build shipyards and then ships. He had limited experience in both having been part of a joint venture building ships for the Maritime Commission in the 1930’s.. Kaiser met with the British with a design of what became the Liberty Ship. It was called an “ugly duckling”. It was basic, austere, and uncomfortable but it had large cargo capacity and was easy to build. The British, who claimed to be the world’s greatest shipbuilders, were sceptical but after Kaiser assured them he could they awarded him the contract but it had to be done his way.

Kaiser bought land on the mudflats at Richmond on San Francisco Bay. He was told by consulting engineers that it would take 6 months to dredge the channel and clear enough land to start construction of his shipyard. Kaiser’s team did it in 3 weeks and in 3 months had constructed their first shipyard.

Kaiser based his production techniques on the Ford Motor Company production line model. Instead of building one ship at a time he built sips in sections with several identical sections being built at the same time then joining the sections by welding instead of rivets. A riveter takes 6 months to train. A welder takes two days.

Kaiser’s shipbuilding programme was for a contract to build ships for Britain before Japan attacked Pearl Harbour. Once the mobilisation of American industry was launched President Roosevelt saw how efficient the Kaiser model was and decreed that construction of warships by the Navy would cease and be handed over to private industry. Kaiser expanded his ship building and ended up with seven shipyards of which four were at Richmond.

Kaiser secured many more contracts which, in turn required more workers. People previously unemployed from all over the country are attracted to the shipyards and as Richmond is far from the usual township facilities Kaiser decides to create his own for the benefit of his workers and offers pay rates comparable to what could be earned working in an aircraft factory in or near a big city.

His first benefit was to provide health care at a cost of 18 cents per week to cover all medical and health care costs. 91% of his workers subscribed making it the largest health care scheme in the USA at the time. Next he created a Health Care company and franchised it out to health care specialists and insurance companies.

Workers flocked from all over the country to join the Kaiser shipyards and by 1943 Richmond had grown into a town of 150,000.Kaiser then embarked on the construction of 93,000 new homes to accommodate the exploding work force. With it he created all of the necessary infrastructure to become a town where people wanted to live. As well as transport he constructed shops, cafes, picture theatres and sporting facilities all open on a 24 hour basis to cater for shift workers.

25% of the shipyard workers were women. To cater for the large number of young families Kaiser built schools, kindergartens and child minding centres with qualified staff so that the mothers could be content at work knowing that their children were being well looked after. In 1933 only 50,000 were employed in shipyards. By 1943 there were 1,700,000.

At the beginning of 1942 a Liberty ship was taking 210 days to construct. By May this was down to 156 days. By July this had come down, on average to 15 days with one being completed in 2 days. Before the war it was taking the US navy shipyards 18 months to complete a Liberty ship type of cargo vessel. Kaiser now had shipyards all around the country and was being feted as a national hero.

Oregon Shipbuilding Corp., 1943. Courtesy Oregon Hist. Soc. Research Lib., Orhi68566

At the start of the war America had only 6 Gato Class submarines. These were the long range submarines that could reach the home waters and shipping channels of Japan. They were complicated and very slow to build. America wanted to do to Japan what Germany had done to Britain, i.e., cut off their supply of vital goods. American shipyards got together and developed production line techniques to build more Gatos. By adopting Kaiser’s methods a new submarine fleet was under construction and by 1944 a new submarine was being launched every 8 days; a far cry from the old US Navy shipyard output. The Gato was America’s first mass produced submarine.

Submarines represented 2% of the US. Navy fleet but they accounted for 30% of all Japanese ships sunk.

Kaiser’s next project was the design and construction of the escort aircraft carrier known as the Casablanca Class. This was a small simple fast moving aircraft carrier that could carry 20 planes and take a few weeks to build using his methods. A conventional aircraft carrier carried 60 or 70 planes and took 3 years to build. There was no time to wait for this. Kaiser met with the Navy board which gave him short shift so he went directly to the President. The President over rode the Navy Board and gave Kaiser a contract to build 50 escort carriers. He undertook to deliver 6 carriers per month and stuck to his deadline. The destruction of the Japanese fleet by the US Navy was achieved by aircraft launched from escort carriers. There were more Casablanca Class ships built than any other class of aircraft carrier on either side during the war.

In 1943 Japan produced 122 major naval vessels. America built 2,634 in the same period.

Despite the outstanding achievements of aircraft and shipbuilding manufacturers American losses on the battle front during Admiral Nimitz’s island hopping strategy were heavy. This was due to the type of landing craft being used which were heavy, slow and did not have shallow draft. Once beached in water too shallow to proceed but too deep for troops to disembark the landing craft were sitting ducks to be picked off by shore based gunfire.

A solution was submitted to the Navy board by a man named Andrew Higgins. Higgins worked in Louisiana servicing offshore oil rigs with a boat of his design. It was fast, highly maneuverable and had very shallow draft. His proposal was rejected by the Navy Board which insisted on retaining the current type of landing craft which it had designed.

Not to be deterred, like Kaiser, Higgins went to see Senator Harry Truman who was on the far right of the Democratic Party and well disposed towards private industry. Truman launched a senate inquiry into the Navy Board which resulted in the Navy Board being sacked and Higgins being awarded a contract to mass produce his boat.

In June, 1944 the US Navy invaded the Marianas using the Higgins boat using the biggest fleet ever assembled to that time. It was an overwhelming success but there were limitations evident in the ability to land heavy equipment such as tanks, artillery and trucks. Kaiser again entered the picture.

Kaiser’s solution was the invention of the LST, the Landing Ship Tank. The LST was designed in Britain but it was manufactured in the USA by Kaiser shipyards. The LST was designed to carry 20 tanks, 27 vehicles and 200 men.

In April, 1945 the US Navy assembled the largest fleet and landing force of the Pacific war when it invaded Okinawa. Over 1,400 ships were involved of which there were hundreds of LST and Higgins landing craft. This was the last great assault of WW2. Four months later the atomic bomb was dropped on Hiroshima and nine days later the war was ended.

The story of the development and production of the atomic bomb has been comprehensively described in my recent article “Hiroshima” so I will not repeat it here. It is suffice to say that this was another example of the superiority of American private industry and enterprise being given a free hand and high level government support to get on with the job by people who really knew what they were doing. There was no muddling through to pay homage to a class system like pervaded British industry. The “can-do” attitude and the refusal to accept that nothing was impossible propelled American industry to heights never dreamed of in 1939.

In 1941, the US Navy consisted of 17 battleships, 8 aircraft carriers, 112 submarines, 653 fighting ships of other classes and no amphibious vehicles. A total of 790. At the end of the war the US Navy was bigger than the British Navy. It had 23 battleships, 99 aircraft carriers, 232 submarines, 2,547 amphibious vehicles and 4,065 ships of other classes. These were the survivors. On top of that, American shipyards also produced the hundreds of ships lost in battle. The US Navy accounted for 70% of the total naval forces of the entire planet.

At the war’s end, Kaiser's shipyards at Richmond, Fairfield and Bethlehem were shut down. Their task was complete. Although the US Navy today is a mere shadow of what it was in 1945 it is still the dominant naval force of the world. The feats of American industry in WW2 placed America in a position of world dominance and leadership that it never aspired to but circumstances and need overcame that lack of ambition.

The advances in industrial production and method developed during WW2 were not to be discarded. They carried over into the peacetime economies and in the field of civilian aircraft production American industry reigned supreme.

The legacies left by these industrial Titans after the war were mixed. Knudsen did not have a private corporation. He was an employed senior executive working for major corporations and died in 1947 leaving only his personal fortune.

Kaiser, on the other hand was the opposite. His interests expanded into other fields and his name still features prominently via Kaiser Steel Corporation and Kaiser Aluminium. His policy of acquiring or creating vertically integrated businesses lead him from one industry to another. A little-known venture was his acquisition of Willys Overland in 1948 and the purchase of part of the Willow Run Ford factory where he began making the Kaiser Jeep for the US Army.

His greatest legacy however was his medical insurance company, Kaiser Permanente Health Care created for his Richmond shipyard workers and inaugurated within the Kaiser Foundation, a non-profit charitable foundation. It is the largest non-profit organisation in the US as at 31/12/2022.

Many household names of the commercial world owe their legacy to the drive of Knudsen and Kaiser during WW2. Names such as Lockheed, Douglas, Northrop, Curtis and Grumman were little companies before WW2. The systems that they developed have been exported as post-war reconstruction to Germany, Japan, and China forming the basis of the current industrial power of these countries.

The greatest legacy in my opinion should be credited to President Roosevelt. Here was a man who was a committed socialist and applied socialism to solving the depression. When war came and he was faced with reality he was big enough to face facts and discard his philosophies in favour of saving his nation by making a 180 degree turn in favour of private enterprise.

In contrast, the British industrial base has withered on the vine. Rather than learn from the American example, when Churchill was defeated at the elections in 1945 and succeeded by his lieutenant on the War Cabinet, Clement Atlee, Britain started on the downward path to socialism. This was accelerated by Wilson and a succession of Labour governments which nationalised all major industry to the point where it no longer exists. Once the mightiest shipbuilding nation in the world, Britain no longer produces any ships. Its famous brands of cars have all disappeared and the manufacture taken over by American and other foreign companies. The one remaining champion of British excellence is Rolls Royce but even that is now back to making only aircraft engines. Its famous cars are now a product of the German company BMW.

Here in Australia American products are still admired and universally popular but there is an underlying atmosphere of self-satisfaction when something adverse happens to America which I find irritating to put it mildly. There is an aura that when something bad happens to America, here there is a perverted sense of achievement in some quarters. I put it down to another branch of our “tall poppy syndrome”.

The reality is that since the end of WW2 the only thing that has stood between Communism and the life that most of the free world enjoys is America. Whether you like it or not that is a fact. If anyone doubts that then just ask yourself what would life be like if America decided to revert to its pre-war isolationist policies? Ask that of any unwashed university graduated latte sipping idiot or a rampant unionist who has the immediate solution to all of the world’s problems and the only response would be something stupid or simply “No appearance Your Worship”.

What would be the result if America withdrew from the UN and told it to remove its HQ to Switzerland? The untold generosity to every beleaguered nation on this planet has not been appreciated by most of them. I would be the first to concede that American diplomacy has failed. They are no good at that at all. What most people take granted is its boundless generosity all paid for by the American taxpayer.

There is not a lot Australia can do of any consequence materially but what we can do is to give America all the moral support that we can in its hour of need. America is now in the grip of heinous criminals and is in desperate need of moral support. The average American is not a coward. He respects the rule of law and for now that keeps him tolerant and overtly submissive but when the shell of the egg breaks it will not be a chicken that will emerge. It will be the American eagle in all of its pent-up fury the like of which we will see as a wake-up like we saw in 1941.

Whenever you hear that Kate Smith rendition of “God Bless America” thank God that you still have the freedom to deride it if you want to.

Here are the words to that song.

God bless America

Land that I love

Stand beside her and guide her

Thru the night with a light from above

From the mountains, to the prairies

To the oceans white with foam

God bless America

My home, sweet home

God bless America

My home, sweet home

God Bless America" is an American patriotic song written by Irving Berlin during World War I in 1918 and revised by him in the run up to World War II in 1938. This later version recorded by Kate became her signature song for the remainder of her career.

BLOG COMMENTS POWERED BY DISQUS